STRATEGIES FOR SUCCESSFUL CORROSION MANAGEMENT

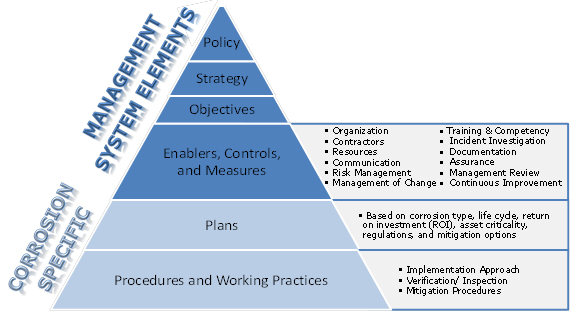

Figure 8-1. The Corrosion Management System Pyramid.

Realizing the maximum benefit in reducing corrosion costs (both direct and consequential) requires more than technology; it requires integrating corrosion decisions and practices within an organizational management system. This is enabled by integrating a CMS within system elements that range from corrosion specific procedures and practices up through organizational policy and strategy; i.e., all levels of the management system pyramid (Figure 8-1). This figure is central to the IMPACT study goal and has been shown throughout this report. It is essential that traditional corrosion management procedures and practices (lower levels of the pyramid) be expressed to policy setters and decision makers (higher levels of the pyramid) in the form and terminologies of organizational policies. Simply, the corrosion practices need to be translated into the language of the broader organization. The organization as a whole must commit to ownership of the CMS and its processes. This means buy-in at all levels within an organization.

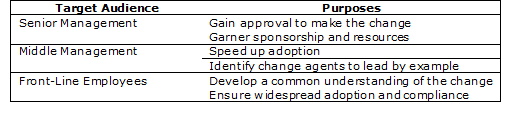

Buy-in can be defined as the acceptance of and commitment to a specific concept or course of action. When asked what buy-in meant, a group of participants in a study came up with a series of definitions that ranged from approval to espousal of a change and included acceptance, support, compliance, commitment, endorsement, and adoption. The general consensus was that all of the definitions were valid yet their applicability depended on the situation and at what level in the organization the buy-in is targeted. For example, the ultimate goal of buy-in may be different for the CEO than for the operation’s staff (see Table 8-1).

Table 8-1. Different Purposes for Buy-In

The adoption of a CMS into an organization’s management system requires buy-in at both the top and bottom. The technical manager (corrosion/integrity/risk/maintenance manager, part of middle management) is the likely promoter of the need for a CMS.

Without buy-in at the top, initiatives have little chance of getting off the ground. Buy-in with senior management is necessary to get approval to move forward and garner resources. To ensure the message is effective, organizations require a business case that includes a clear statement of the problem, outlines its impact on the organization, lists the required resources, and includes the outcome in terms of cost reductions, increased productivity, improved quality, and/or decrease in risk (environmental, safety, business interruption, public relations, etc.).

Initiatives have also failed because concerns and issues were not addressed at lower levels in the organization. Buy-in with front-line employees is to create a shared understanding around the change and ensure compliance. Individuals may understand the change but take a wait and see stance until they see how it will negatively affect them personally.

To facilitate business case communication between corrosion professionals and senior management leading to integration of a CMS throughout an organization’s management system, the following steps are necessary.

- The corrosion professional should broaden his competence with respect to business tools, to include financial decision-making, risk assessment, and management systems. Use of financial and risk assessment tools should be a normal and expected activity for evaluating corrosion control expenditures. Whenever relevant and possible, life cycle costing should be considered.

- Universities and professional societies should incorporate management system elements and supporting tools into corrosion engineering and technology curricula.

- Corrosion professional societies should promote management system elements and supporting tools within symposia, seminars, workshops, and technical exchange groups.

- Communication between those inside and outside of the corrosion profession should be in the language of the external decision-maker (e.g., operations or business manager) or stakeholder (e.g., regulatory, policy, or public) with the goal of business improvement.

- Corrosion professional societies, such as NACE International, should develop training similar to ASME’s business communication program described in Education and Training, with a specific focus on corrosion professionals to educate and train corrosion professionals to better communicate to those outside of the profession. Corrosion professionals should not expect an organization’s business leaders and policy makers to learn their technical language. These communications range from justifying a single corrosion control activity to recommending policy changes. This has the added benefit of moving the corrosion professional away from what is often perceived as alarmist language toward enabling sound business practice.

- Industry spokespersons must emphasize business strategy and/or public policy when advocating positions to those outside of the corrosion profession. Corrosion professional societies, including NACE International, have worked hard to make organizational leaders and policy makers aware of the cost of corrosion and the cost-saving opportunities that can be realized by sound corrosion control. This was a primary goal of the 2002 cost of corrosion report. Using the principles of CMS will make these arguments more persuasive.

- Organizations should develop, integrate, and implement corrosion management elements into an organization’s overall management system.

- NACE International should take the lead in educating asset owners on how to (and the value of) integrating a CMS into their organization’s management system.

- Industry should develop a consensus standard on corrosion management to define expectations of standard practice for corrosion management. This is a first step in the process of institutionalizing CMS into standard industry practice.

- Organizations should adopt a framework and guidelines for integrating corrosion control into an organizational management system such as discussed in the Corrosion Management System Framework. Appendix B provides a how-to approach on building a best practice CMS.

- Regulators should incorporate corrosion management effectiveness into regulatory and other oversight practices.

- Organizations should align long-term, applied, and basic corrosion R&D with the strategic goals of the organization consistent with the principles of CMS.