Performance Gaps Determined by the Survey Results

Many of the common practices of the top performers become gaps for the majority of organizations. In addition, the surveys also indicated where consistently low scores were recorded. These areas establish the performance gaps in a CMS. The following are considered performance gaps based on the self-assessment surveys.

Only 14% of participants believe that their CMS is robust. This leaves room for significant improvements in a CMS. Seventy five percent of survey participants do not have corrosion management performance integrated into organizational performance metrics.

Only about half of total respondents state that their asset design strategy addresses the following with respect to corrosion: regulations; health, safety, and environmental (HSE) concerns; the intended life of the asset; and the functional requirements.

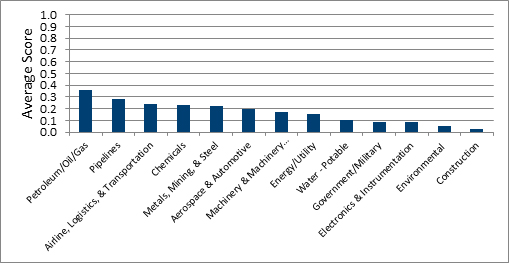

Most corrosion management programs do not address abandonment, decommissioning, or mothballing (ADM). The petroleum/oil/gas and pipelines industries provide the most consideration for this phase of the asset life cycle (see Figure 4-20). ADM poses a significant organizational risk (based on the asset involved) when taking into account environmental, safety, and financial considerations.

Figure 4-20. Average scoring for corrosion management addressing ADM.

Figure 4-21. Average score for impact of resources by geography.

Corrosion management resourcing exhibited relatively low scores across all regions, indicating that resourcing was more ad-hoc than planned (see Figure 4-21). This claim is backed by a comment provided by a Chinese survey participant:

“[My organization] is missing the expertise to build corrosion subject matter expert teams. Non-experts cannot easily find hidden corrosion issues.”

Without adequate resources it would be difficult to implement a robust corrosion management system.